What is Contract Lifecycle Management (CLM) and its impact on quality lifecycle management

What is Contract Lifecycle Management (CLM) and its impact on quality lifecycle management Contract Lifecycle Management (CLM) is a structured approach to managing contracts from[…]

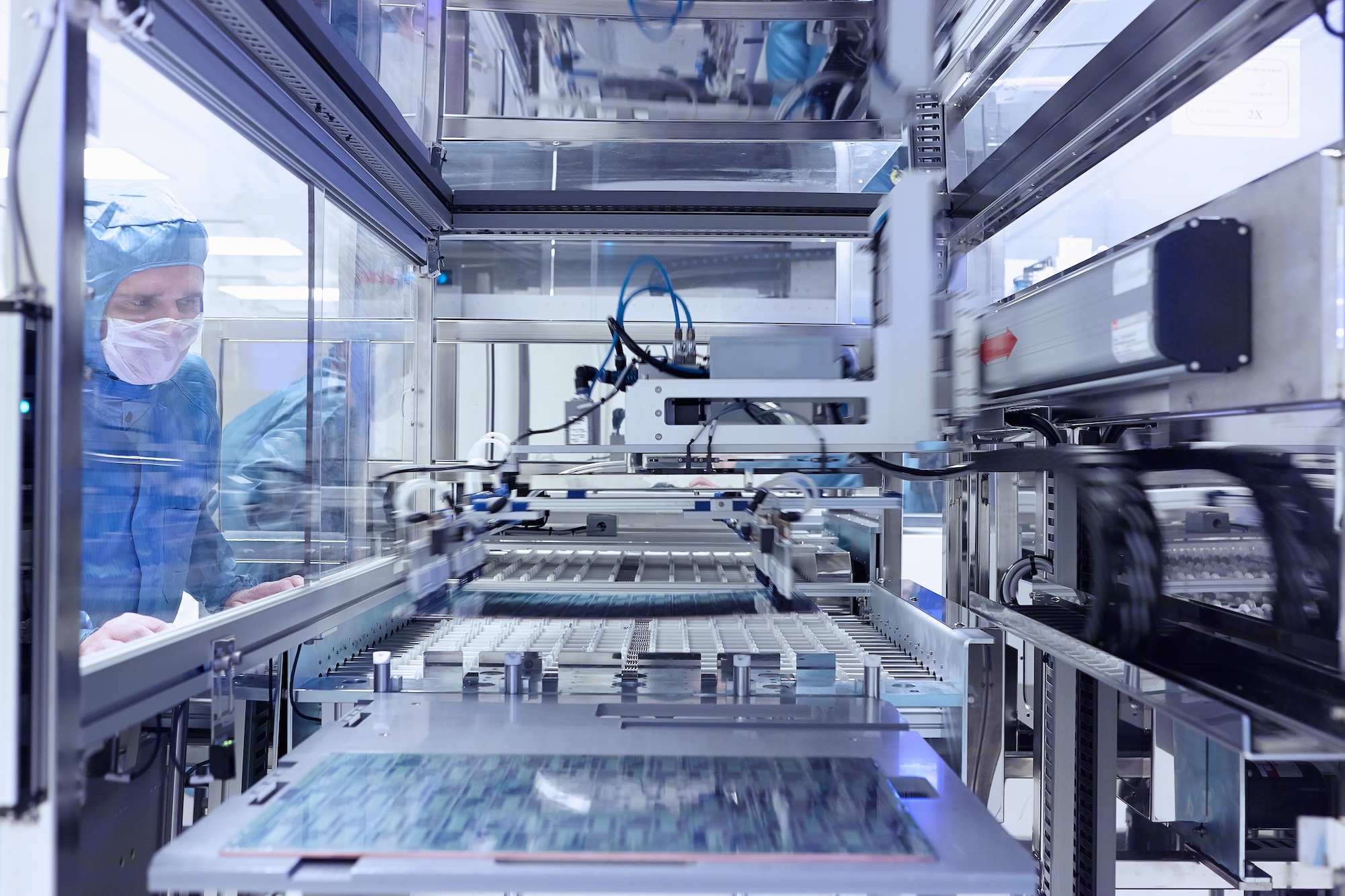

Prolonging Equipment Lifespan and Optimizing through Predictive Maintenance

How Predictive Maintenance Can Benefit Supplier Equipment. Supplier Quality Engineers (SQEs) and Predictive Maintenance (PdM) are closely intertwined, making it essential for SQEs to have[...]

ABC to approach Enterprise Risk Management on manufacturing with ease

In today’s complex business environment, organizations face a myriad of potential risks, including cyberattacks, data breaches, system failures, and natural disasters. Effective risk management is[…]

Securing the Chain: Why Cybersecurity Matters in Modern Manufacturing

As a supplier quality engineer, you’re the guardian of quality throughout the manufacturing supply chain. You ensure parts meet specifications, processes are efficient, and ultimately,[…]

101 on RCA tools and techniques

In the fast-paced world of manufacturing, critical quality and efficiency are essential for success. However, unexpected issues and production roadblocks can disrupt operations and impact[…]

In-depth on CFR 11

The U.S. Food and Drug Administration (FDA) plays a vital role in protecting public health by regulating medical devices. Part 11 of Title 21 of[…]

Facing regulatory compliances in electronic manufacturing with Kiuey

The supply chain in electronic manufacturing faces numerous challenges, with regulatory compliance emerging as a major source of risk for Original Equipment Manufacturers (OEMs). This[...]

How to comply with ISO 13485 with the aid of Kiuey

Think of ISO 13485 as the golden ticket to medical device manufacturing. It's the internationally recognized standard for quality management systems, ensuring the safety and[...]

How to counter non-conformances through digital tools and a prevention approach

Picture this: you're steering the ship of quality control, ensuring every product sails smoothly through manufacturing. Suddenly, a storm hits - non-conformances due to poor[...]

Subscribe to our newsletter.

Your go-to destination for insights, best practices, and innovative solutions in supplier quality assurance.

Recent Posts

How stress impacts quality outcomes

February 5, 2026

Categories

Let's talk to see how PPAP Manager can help your company to save time and money.