Linking Quality Assurance to Customer Satisfaction in Manufacturing

In today’s fiercely competitive market, customer satisfaction has become the cornerstone of business success. For manufacturers, delivering products that not only meet but exceed customer expectations is paramount. This is where quality assurance (QA) plays a pivotal role. By ensuring that products are consistently reliable, durable, and meet specified requirements, QA directly impacts customer satisfaction[…]

Securing the Chain: Why Cybersecurity Matters in Modern Manufacturing

As a supplier quality engineer, you’re the guardian of quality throughout the manufacturing supply chain. You ensure parts meet specifications, processes are efficient, and ultimately, the final product is reliable and safe. But in today’s interconnected world, a new threat lurks – cyberattacks on the supply chain. Why Cybersecurity Matters in Manufacturing Modern manufacturing relies[…]

101 on RCA tools and techniques

In the fast-paced world of manufacturing, critical quality and efficiency are essential for success. However, unexpected issues and production roadblocks can disrupt operations and impact the bottom line. To achieve long-term success, manufacturers need to go beyond simply fixing problems; they need to identify the root cause to prevent them from recurring. This is where[…]

The Kaizen Advantage: Empowering Supplier Quality Engineers for Continuous Improvement

In today’s competitive landscape, ensuring consistent supplier quality is paramount. Supplier Quality Engineers (SQEs) play a critical role in this process, acting as a bridge between the buying organization and its suppliers. But maintaining and improving quality is an ongoing journey – a concept perfectly captured by the Japanese philosophy of Kaizen. Kaizen, meaning “continuous[…]

Evolving supplier relationship management to the diamond model

Supplier relationship management (SRM) has undergone a significant transformation in recent years. What was once a transactional, hierarchical system has evolved into a collaborative and strategic partnership model. This shift reflects the growing recognition that strong supplier relationships are essential for a company’s success in today’s competitive landscape. The Traditional Pyramid: A Focus on Cost[…]

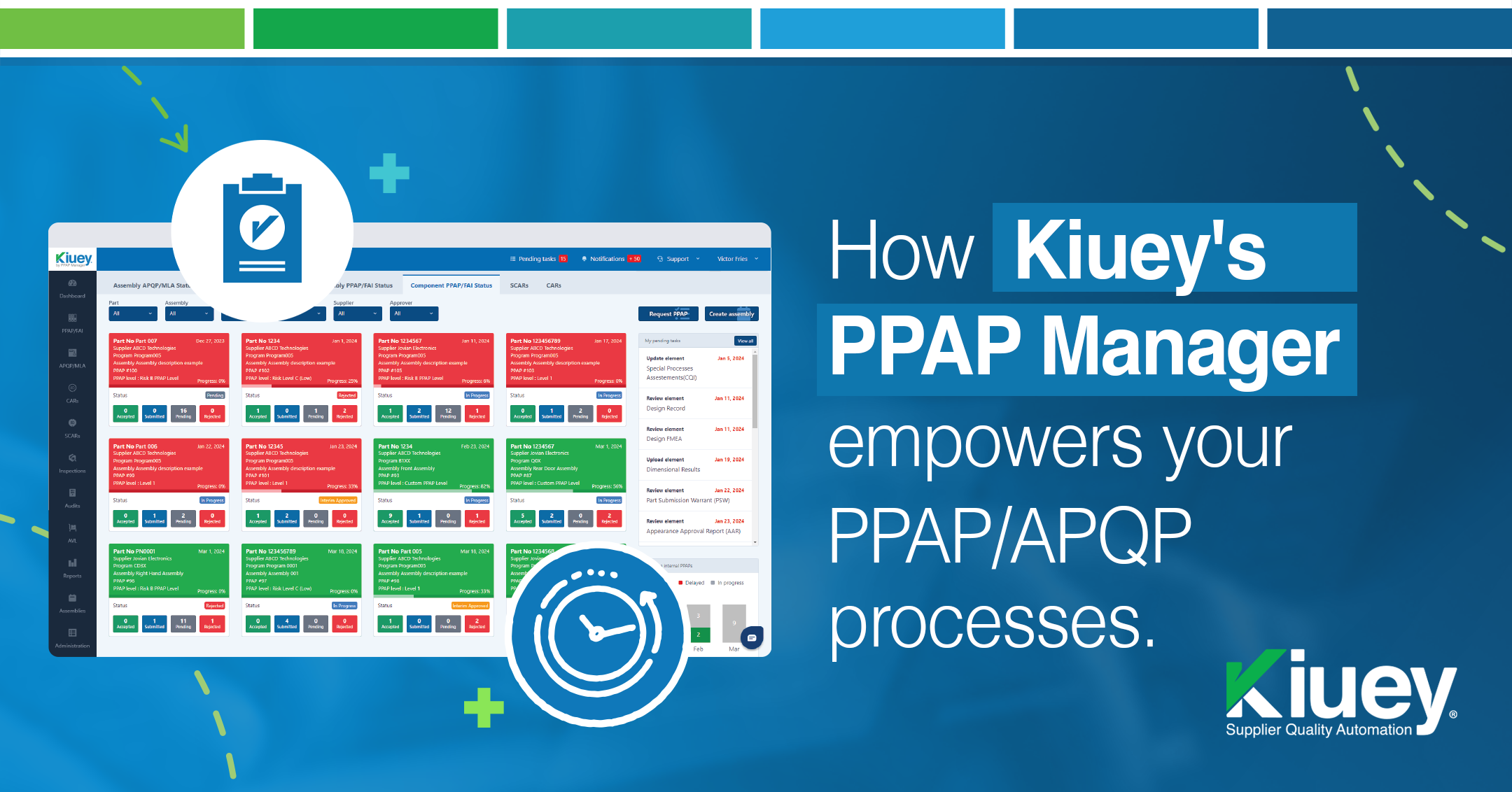

How Kiuey’s PPAP manager empowers your PPAP/APQP processes

In today’s globalized supply chain, streamlining the Production Part Approval Process (PPAP) is crucial for both manufacturers and suppliers. Online PPAP management tools must offer a significant advantage by automating tasks, improving communication, and ensuring compliance. But not all tools are created equal, and there’s where we portrait that our PPAP Management tool is different.[…]

Dangers of Stagnation: Why Rejecting New Technology is Harmful for SQEs

The frustration crackled in Sarah’s voice as she slammed her laptop shut. “This new system is a nightmare,” she grumbled to her colleague, David. Sarah, a seasoned Supplier Quality Engineer (SQE), had spent the morning wrestling with a recently implemented quality management platform. Does that short story sounds familiar to you? The relentless march of[…]

Planning and Prioritization over Time Management: The Path to Surpass SQEs’ Time Havoc

Imagine this: John, a Supplier Quality Engineer (SQE), rushes into a meeting ten minutes late, frazzled and flustered. He forgot a crucial document for the supplier audit presentation, and the team is already behind schedule due to his earlier delay reviewing a corrective action plan. This scenario, unfortunately, isn’t uncommon for SQEs juggling various demands[…]

How Supplier Quality Audits Drive Zero Defect Manufacturing

The concept of “zero ppm” (parts per million) or “zero defects” has been around since the 1960s. It represents a continuous pursuit of excellence in manufacturing and development processes. Achieving “Zero Defect” translates to significant benefits – reduced costs associated with failure and increased revenue through enhanced customer satisfaction. While applicable to any organization, zero[…]

Unlocking Business Excellence: A Guide to ISO 9001 and Internal Audits

Over a million organizations worldwide trust the ISO 9001 Quality Management System (QMS) to achieve consistent success. This globally recognized standard helps businesses deliver products and services that consistently meet customer expectations, ultimately driving satisfaction and loyalty. ISO 9001’s versatility is a key strength – it can be applied by any organization, regardless of size,[…]

Subscribe to our newsletter.

Your go-to destination for insights, best practices, and innovative solutions in supplier quality assurance.Recent Posts

Robots in manufacturing: from AI to cobots

July 10, 2024

Categories

Tags

AIAG

AS9100

automotive industry

Cp

Cpk

customer satisfaction

cybersecurity

digital tools

electronic manufacturing

IATF

incoming inspections

ISO 9001

ISO 13485

manufacturing

Nonconformances

PFMEA

Pp

ppap

PPAP Management

PPAP regulations

Ppk

process audits

Process Capability Analysis

QA regulations

quality assurance

quality control

quality technologies

REACH

regulatory compliances

risk management

SCARs

sqes

supplier audit

supplier audit checklist

Supplier Quality

Supplier Quality Data

supplier quality engineers

Supplier Quality Management

supplier scorecards

supply chain

Supply Chain Management

VDA

VDA 6.3

VDA AIAG PFMEA

VDA Auditor

Let's talk to see how PPAP Manager can help your company to save time and money.