Unveiling the Power of PPAP Manager by Kiuey for the automotive industry

In an ever-evolving automotive industry, quality control and supplier performance management are non-negotiable. The need for precision and efficiency has given rise to innovative solutions, and one tool is set to transform the game.

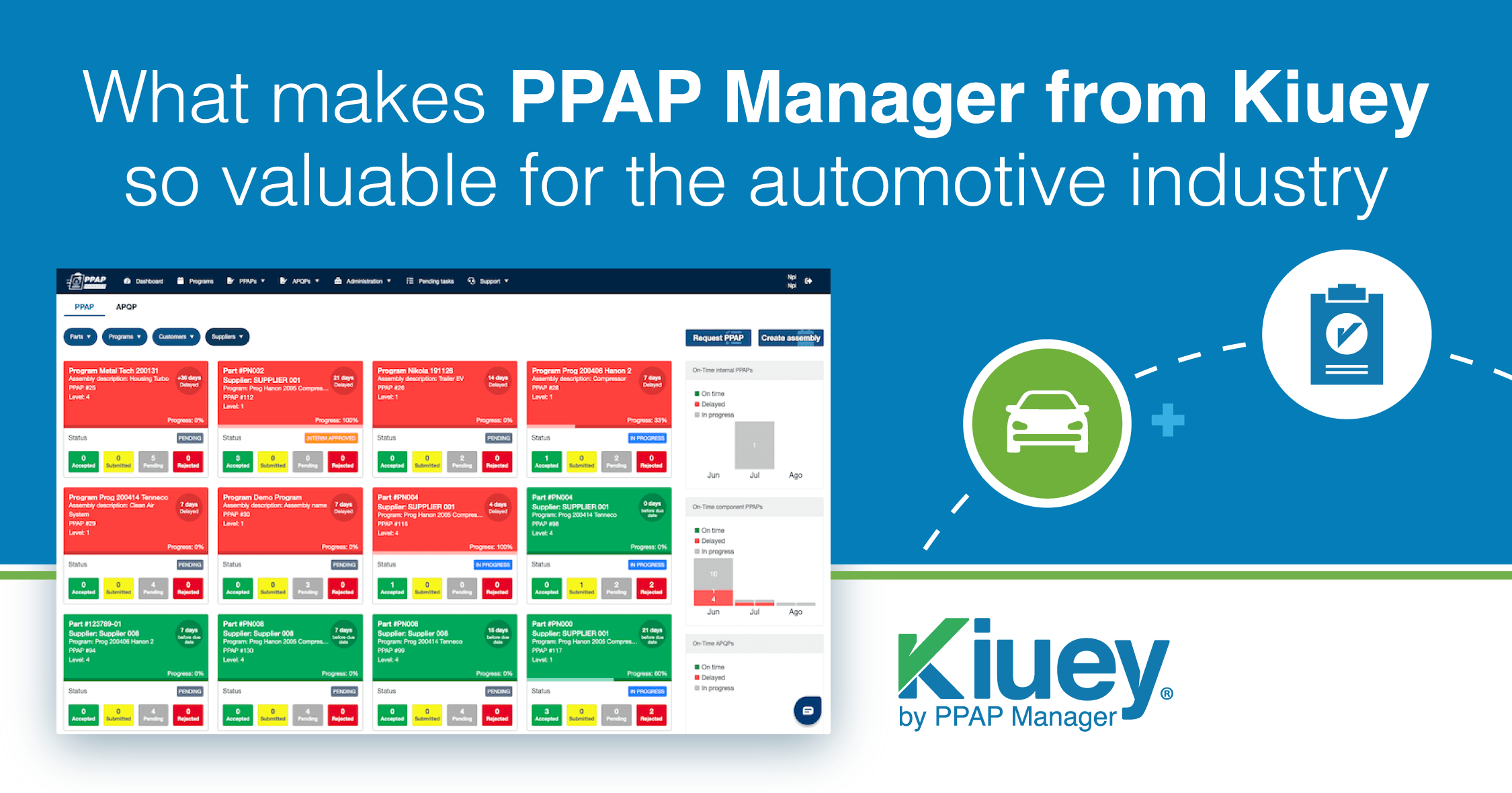

That’s where it’s worth to get to know PPAP Manager from Kiuey, a platform that helps you to streamline PPAP, APQP, and perform Quality Concern Management with ease. In this article, we’re about to unravel how this tool can empower Supplier Quality Engineers and revolutionize the way quality is managed in the automotive sector.

The Power of PPAP Manager by Kiuey

Supplier Quality Engineers have long been grappling with the complexities of managing PPAP (Production Part Approval Process), APQP (Advanced Product Quality Planning), and Corrective Actions. The traditional methods involved heaps of paperwork, cumbersome spreadsheets, and endless email exchanges – a time-consuming and error-prone nightmare.

Benefitting the Supplier Quality Engineer: Imagine having all your PPAP documentation, APQP planning, and corrective actions management consolidated into one streamlined platform. No more shuffling through folders or endless back-and-forth emails.

With Kiuey PPAP Manager, Supplier Quality Engineers can now:

- Access enhanced Efficiency: Easily access, update, and track all PPAP and APQP documents in one place, reducing the risk of errors and ensuring real-time collaboration among team members.

- Develop seamless Collaboration: Collaborate effortlessly with colleagues and suppliers, streamlining communication and ensuring everyone is on the same page, thus reducing delays and ensuring timely approvals.

- Achieve Error Reduction: Say goodbye to manual data entry errors. Kiuey’s smart automation features can significantly reduce data entry errors, saving time and resources.

- Close the Quality Concerns Faster: Identify and address issues promptly with integrated corrective action tracking. No more lost emails or missed deadlines.

PPAP Manager from Kiuey offers unbeatable value for money, allowing your engineers to focus on the tasks that really matter.

And just to ponder the cost /benefit ratio of implementing our tool, we would like to ask you a pair of critical questions:

- How much time could you save by consolidating your quality management processes into one platform?

- How many times have you been frustrated by fragmented communication in your quality management?

You see, in a competitive industry where efficiency, quality, and compliance are paramount, embracing innovation is not an option; it’s a necessity. The integration of PPAP, APQP, and Quality Concerns management in a single platform offers a quantum leap in productivity and precision.

In conclusion, Kiuey’s PPAP Manager is not just a tool; it’s a game-changer; with it, Supplier Quality Engineers can now dedicate more time to proactive quality improvement and innovation.

The advantages it offers in terms of efficiency, collaboration, error reduction, and cost-effectiveness are unmatched. The next step of quality management in the automotive industry is here, and it’s powered by Kiuey. Schedule a demo now with us and experience firsthand how this innovative tool can elevate your quality management game to new heights.