Supplier quality engineers can constantly feel they’re chasing down information on supplier performance. In more than one occasion, they tend to drown in a sea of spreadsheets and inconsistent data.

While there are many approaches to solve this issue, the supplier scorecard is the basic and one of the most important tools to foster quality management approach and monitoring.

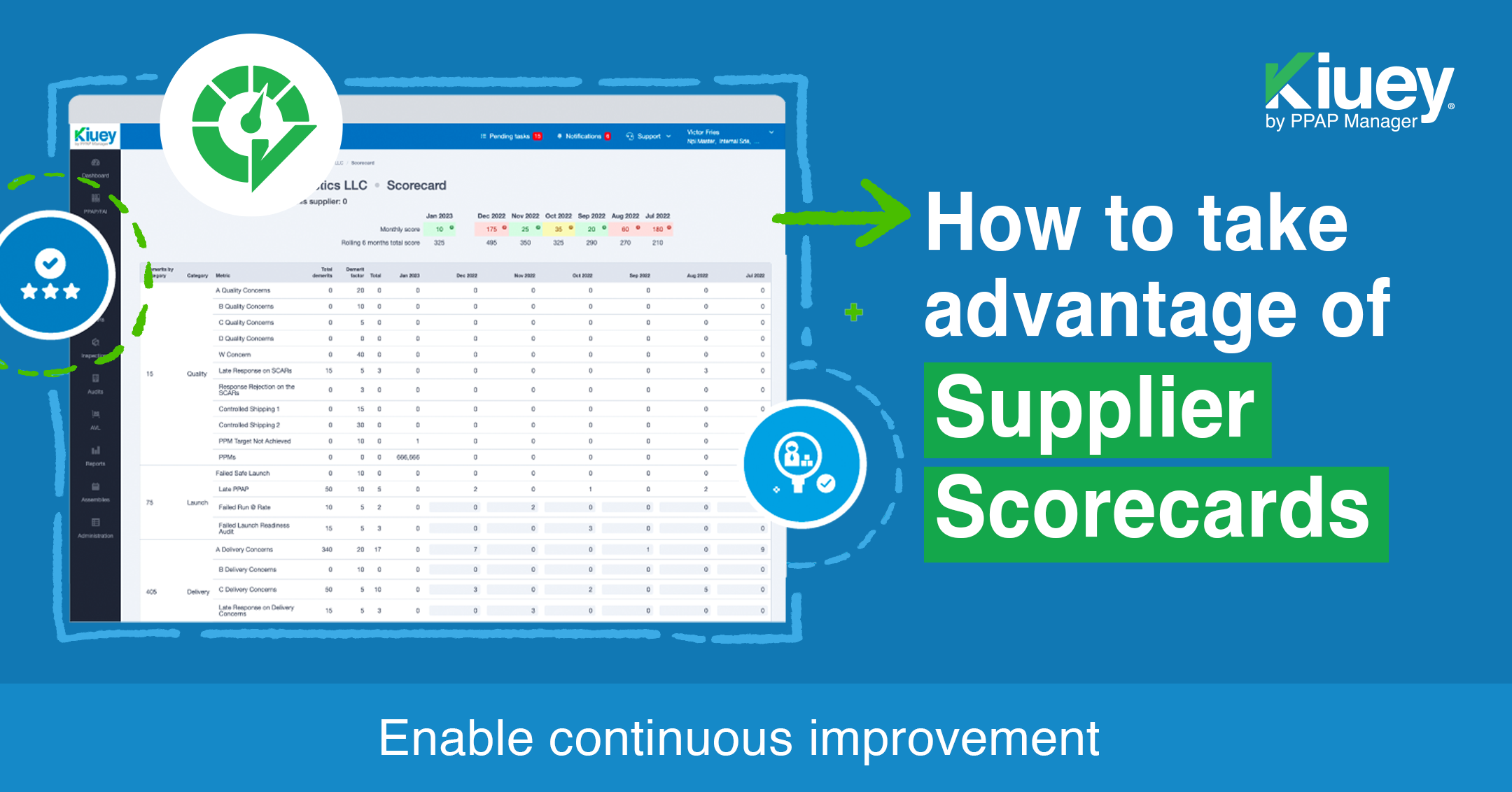

In a nutshell, a supplier scorecard improves supplier collaboration and helps to build a quality-driven supply chain, all through a single and centralized platform that provides a comprehensive overview the supplier’s performance across critical dimensions like quality, delivery, and cost.

Building the Foundation: Defining Your Goals and Metrics

The cornerstone of an effective supplier scorecard lies in clearly defined objectives. What are your critical quality criteria for your suppliers? Is it on-time delivery, defect rate, or cost-efficiency? Identifying these priorities is crucial, as they will guide the selection of relevant metrics to be included in your scorecard.

Think about the following:

- Quality: Defect PPM (Parts Per Million), scrap rate, rework costs

- Delivery: On-time delivery percentage, lead times, reliability

- Cost: Total procurement cost, price fluctuations, payment terms

Remember, you should tailor your metrics to your specific industry context and supplier relationships.

Engaging Your Audience: Collaborating through the supplier scorecard

Transparency and collaboration are key ingredients for a successful supplier scorecard implementation. Engage your suppliers in the process by:

- Communicating your expectations: Clearly defining the chosen metrics and their significance.

- Gathering their feedback: Involving them in the process can foster a sense of ownership.

- Providing training and support: Equipping them with the necessary knowledge to effectively utilize the scorecard system.

By fostering a collaborative approach, you not only gain valuable insights from your suppliers but also cultivate stronger, mutually beneficial relationships.

Utilizing Supplier Scorecards for Continuous Improvement

Once your supplier scorecard is in place, it transforms into a dynamic tool for continuous improvement. Regularly monitoring performance allows you to:

- Identify trends and potential issues: Proactively address any concerns before they escalate.

- Benchmark performance: Compare supplier performance against industry standards or internal targets.

- Drive improvement initiatives: Collaborate with underperforming suppliers to implement corrective actions.

Supplier scorecards empower you to move beyond reactive problem-solving to proactive, data-driven decision-making, ultimately leading to a more resilient and efficient supply chain.

Embracing a Data-Driven Future

Supplier scorecards represent a paradigm shift in supplier quality management. By embracing this data-driven approach, you gain the ability to:

- Enhance transparency and communication throughout the supply chain.

- Make informed decisions based on reliable and consistent data.

- Drive continuous improvement and foster stronger supplier relationships.

Ready to unlock the potential of supplier scorecards? Check out our AVL Supplier Manager solution, in which you can collaborate instantly with suppliers and automate your suppliers’ qualifications.