AI + Calibration: Towards a standard digital calibration certificate

Calibration, a cornerstone of quality assurance in industries like pharmaceuticals, food and beverage, and chemicals, is undergoing a significant transformation. The emergence of digital calibration certificates (DCCs) and artificial intelligence (AI) is poised to revolutionize this critical process, streamlining it while enhancing accuracy and efficiency. Here comes DCC At the heart of this revolution lies[…]

Project Management Basics for Supplier Quality Engineers

Supplier Quality Engineers (SQEs) play a critical role in ensuring the quality of products and services procured from external suppliers. Effective project management is essential for SQEs to successfully manage quality-related activities, improve supplier relationships, and achieve organizational goals. Project Management Fundamentals for SQEs While program management provides a broader framework for managing multiple projects,[…]

IMDS: A strategic tool for supplier quality engineers

The International Material Data System (IMDS) has become an indispensable tool for supplier quality engineers operating within the automotive supply chain. By providing a centralized platform for managing material information, IMDS enables efficient compliance, risk mitigation, and product sustainability. As we navigate the complexities of 2024, understanding its evolving role and significance for supplier quality[…]

ABC on ISO/IEC 17025 Calibration Certificates

Have you ever received a calibration certificate and wondered what all the technical jargon meant? It’s a common experience for many of those who rely on calibrated equipment for their work. A calibration certificate is a crucial document that provides essential information about the accuracy and reliability of your measuring instruments. In this blog post,[…]

What is surface finish measurement and how it improves product performance

Surface finish, often measured by surface roughness, is a critical aspect of product quality that can significantly impact a product’s performance, durability, and appearance. For supplier quality engineers, understanding and ensuring optimal surface finishes is essential for delivering high-quality components. Key Surface Texture Characteristics Roughness: The microscopic peaks and valleys on a surface. Lay: The[…]

Optimizing Measurement Uncertainty for Enhanced Product Quality

Measurement uncertainty, a fundamental concept in quality control, is the range within which the true value of a measurement is expected to lie. While it’s impossible to eliminate measurement uncertainty completely, it can be minimized through various strategies to enhance product quality. Measurement Uncertainty: What to do Selecting Appropriate Measurement Equipment The foundation of accurate[…]

Integrating Soft Skills into Problem Solving Techniques for Supplier Quality Engineers

Supplier quality engineers play a crucial role in ensuring the quality of products and services delivered by suppliers. While technical skills are essential, soft skills are equally important in building strong relationships, fostering trust, and effectively addressing quality issues. Key problem solving techniques integrated with soft skills Empathetic Root Cause Analysis By actively listening to[…]

Basis on developing a quality culture with suppliers

In today’s competitive landscape, ensuring the quality of products and services is paramount. A strong supplier quality management system is essential to maintaining high standards throughout the supply chain. As a supplier quality engineer, your role is pivotal in cultivating a quality culture within your organization’s supply base. 1. Define Clear Expectations: Quality Standards: Develop[…]

ABC for ISO 17012

The advent of digital technologies has revolutionized various industries, and the field of quality management is no exception. Remote auditing, once a relatively uncommon practice, has become increasingly prevalent, offering a more flexible and efficient approach to assessing supplier performance. To provide a standardized framework for remote auditing activities, the International Organization for Standardization (ISO)[…]

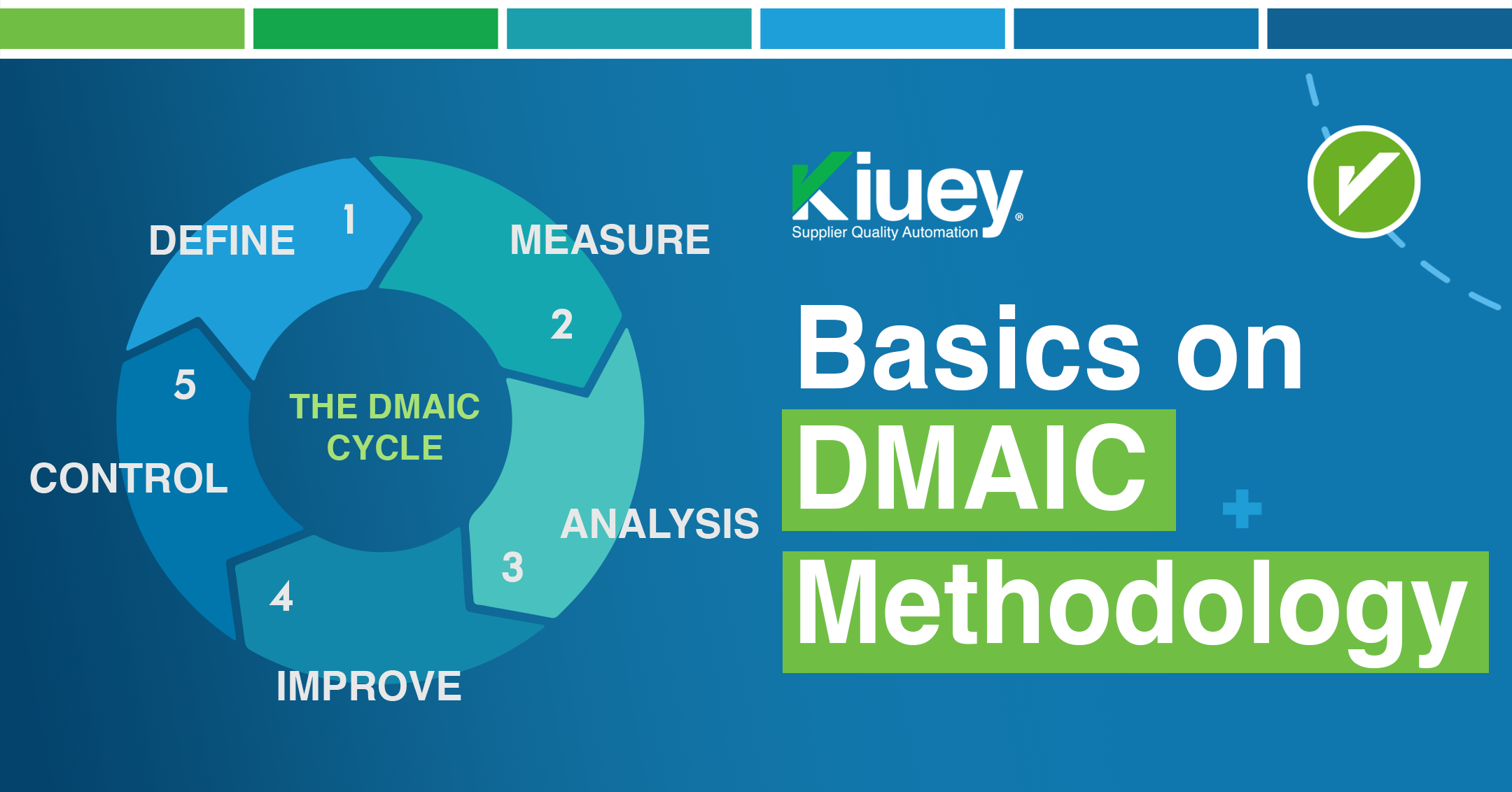

Basics on DMAIC methodology and its utility for SQEs

The DMAIC methodology, a structured approach to problem-solving and process improvement, has become a cornerstone of Six Sigma and Lean manufacturing. For Supplier Quality Engineers (SQEs), DMAIC offers a powerful framework to identify, analyze, and eliminate defects in supplier processes, ultimately enhancing product quality and reducing costs. Understanding DMAIC DMAIC stands for Define, Measure, Analyze,[…]

Subscribe to our newsletter.

Your go-to destination for insights, best practices, and innovative solutions in supplier quality assurance.Recent Posts

AI + Calibration: Towards a standard digital calibration certificate

October 21, 2024

Project Management Basics for Supplier Quality Engineers

October 19, 2024

IMDS: A strategic tool for supplier quality engineers

October 16, 2024

ABC on ISO/IEC 17025 Calibration Certificates

October 14, 2024

Tags

ai

AS9100

audits

automotive industry

CLM

compliance manufacturing

contract lifecycle management

customer satisfaction

cybersecurity

data analysis

IATF

Internet of Things

IoT

ISO 9001

ISO 13485

manufacturing

Nonconformances

ppap

PPAP Management

PPAP regulations

problem solving

problem solving techniques

QA regulations

quality assurance

quality control

quality mindset

quality technologies

REACH

risk management

SCARs

sqes

supplier audit

supplier audit checklist

supplier audits

supplier compliance

Supplier diversification

Supplier Quality

supplier quality engineers

Supplier Quality Management

Supplier Selection

supply chain

surface finish

surface finish measurement

Sustainability

VDA

Let's talk to see how PPAP Manager can help your company to save time and money.