Mastering the IATF 16949: A Supplier Quality Engineer’s Toolkit

The International Automotive Task Force (IATF) 16949 standard serves as the cornerstone for quality management in the automotive supply chain. As a Supplier Quality Engineer[…]

What to expect on Hannover Messe 2024 (besides meeting with Kiuey)

Hannover Messe, the world’s leading industrial trade fair, is set to take place from April 22nd to 26th, 2024. This year’s event focuses on achieving[…]

Step by step of the action plan after supplier audit

Supplier quality audits are essential for ensuring the smooth functioning of your supply chain. By evaluating a supplier’s adherence to quality standards, you can identify[…]

Supplier audit “MUSTs” for securing supply chain

Selecting the right suppliers is crucial for any manufacturing business. They play a vital role in the quality of your finished products, your production timeline,[…]

Conquering PPAP Level 5 Submission: A Flawless Guide

The Production Part Approval Process (PPAP) is the cornerstone of quality control in the automotive and aerospace industries. Level 5, the most demanding level, ensures[…]

Overcoming Inconsistent Supplier Quality Data: A Challenge for Effective Supply Chain Management

Supplier quality engineers (SQEs) play a critical role in ensuring the quality and consistency of materials and products sourced from external vendors. However, their ability[…]

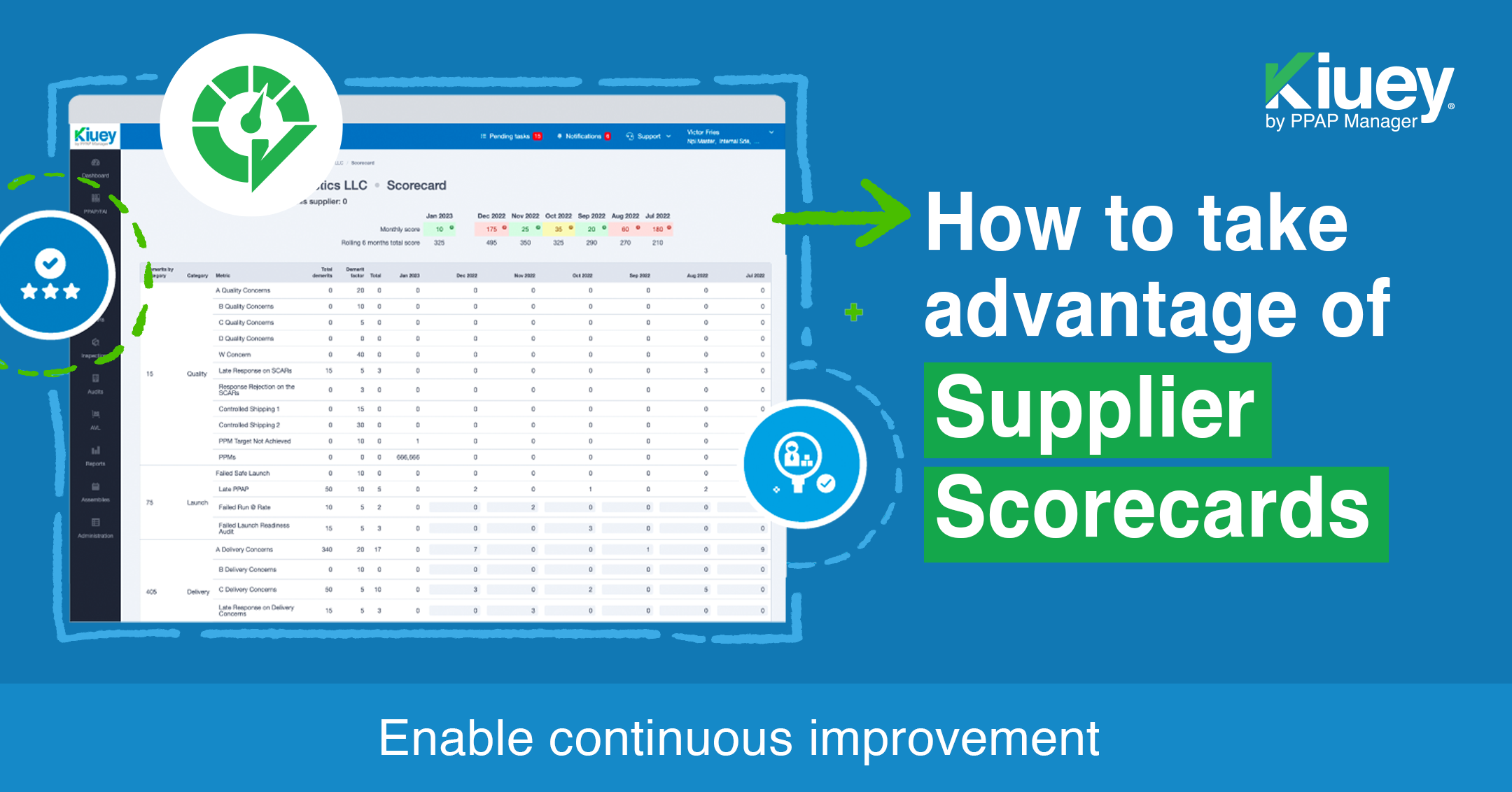

How to take advantage of supplier scorecards to enable continuous improvement

Supplier quality engineers can constantly feel they're chasing down information on supplier performance. In more than one occasion, they tend to drown in a sea[...]

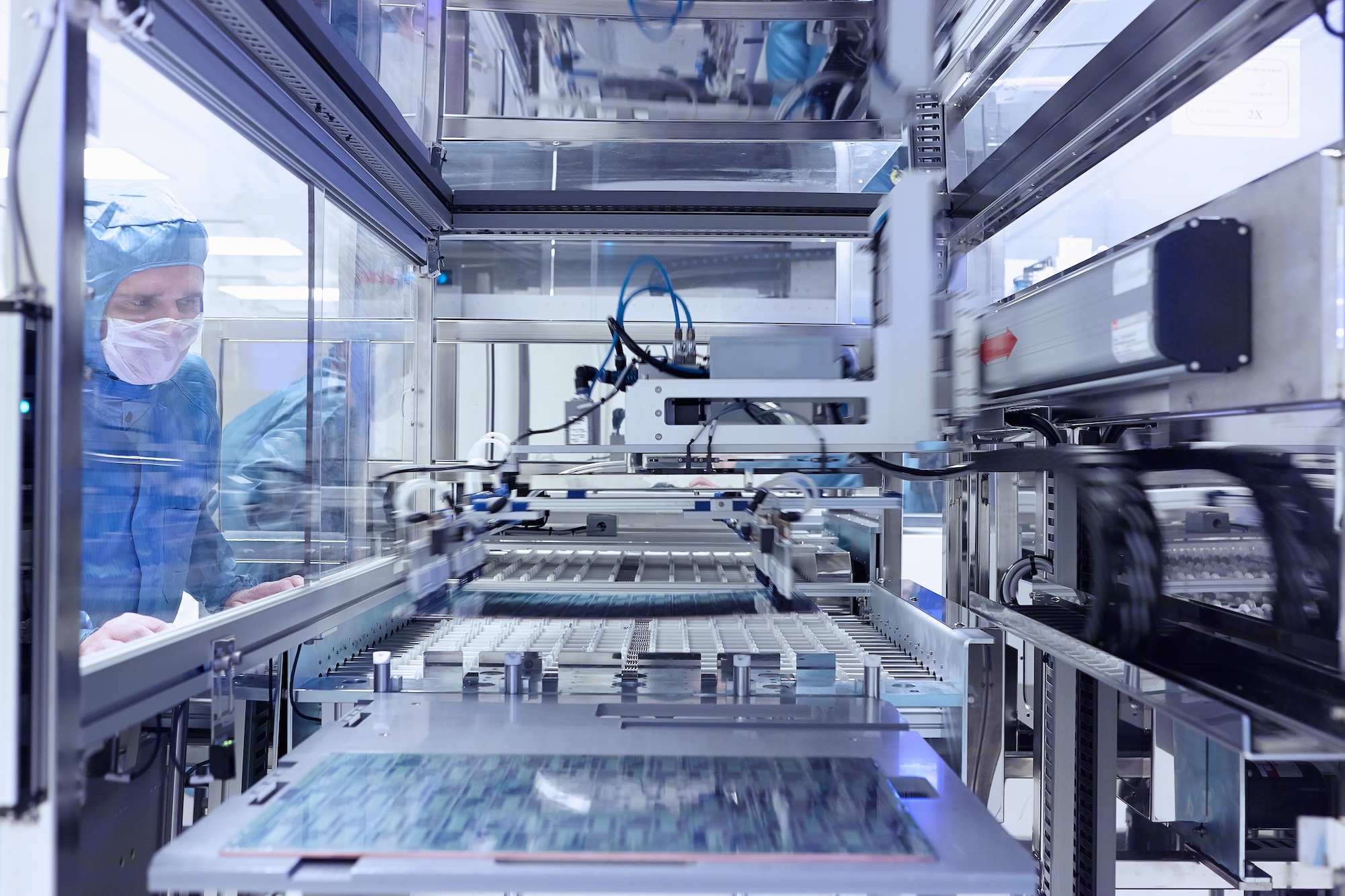

Facing regulatory compliances in electronic manufacturing with Kiuey

The supply chain in electronic manufacturing faces numerous challenges, with regulatory compliance emerging as a major source of risk for Original Equipment Manufacturers (OEMs). This[...]

Key elements to understand AS9100 and comply with the aid of Kiuey

Aerospace manufacturing is sure a challenge. Besides the necessities and complexities of a supplier quality management scenario already present in the industry, supplier quality engineers[...]

Subscribe to our newsletter.

Your go-to destination for insights, best practices, and innovative solutions in supplier quality assurance.

Recent Posts

The ROI of Lean ISO Management Systems

January 31, 2025

The Power of Second Chance Manufacturing Programs

January 30, 2025

The Secret to Customer Delight: Embedded Quality

January 28, 2025

The Psychological Impact of Stress on Quality Outcomes

January 28, 2025

Categories

Let's talk to see how PPAP Manager can help your company to save time and money.